There is a vast array of different types of cars on the road. The sheer variety of car types is necessary to fulfill all the different functions and preferences required by the automotive market. Essentially, the range of vehicle body styles is analogous to a well-stocked toolbox; each is designed to serve a specific purpose more efficiently than any other, yet all are required to keep society running.

Understanding the form and function of each type of car goes beyond personal preference. The modern economy makes it essential for both individuals and companies alike to cultivate a working knowledge of the relative pros and cons of each vehicle’s body style. After all, the utility of a given vehicle goes beyond the sum of its parts. It’s not enough to simply understand that both trucks and sports cars have powerful engines; the holistic differences in design features between the two mean that a sports car is a poor choice for towing a load while trucks are rarely optimal for tight handling and high speeds.

Such considerations and comparisons between types of vehicles abound in daily life. For example, both coupes and minivans are common choices for commuters, but the former is usually far more economical for single people while the latter excels for large families. The choice between a sedan, wagon, or SUV may seem superficial until one considers the nuanced advantages each offers to different lifestyles and work requirements. The point is, it pays to understand what problems each car type is designed to solve in order to pick the best tool for the task.

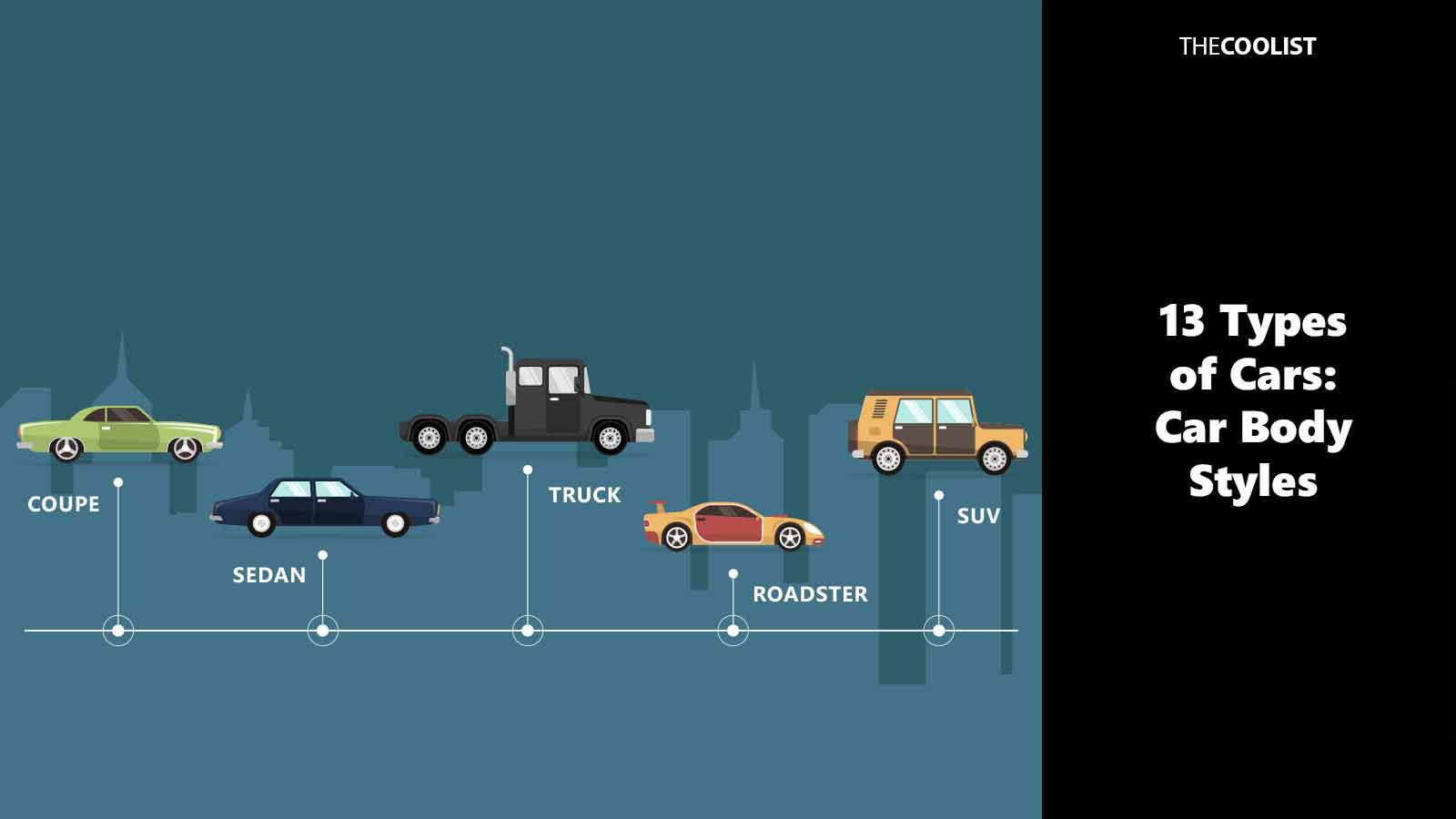

Below is a high-level overview of the main 13 types of cars. We define their intended use cases, weigh their pros and cons, and examine the most prevalent makes and models for each vehicle’s body style to help you make a more informed decision about which is best for you.

| Car Type | Definition | Pros | Cons | Price Range |

| SUV | Sport Utility Vehicle, versatile in performance, capability, and size. | Spacious, versatile, good off-road and towing capabilities. | They can be expensive and less fuel-efficient than smaller cars. | $25,000 – $70,000 |

| Crossover | A blend of SUV and sedan features, offering versatility and efficiency. | Efficient, versatile, and better fuel economy than SUVs. | Less off-road capability than SUVs, sometimes smaller cargo space. | $20,000 – $50,000 |

| Sedan | Traditional car with a separate trunk, known for comfort and efficiency. | Comfortable, efficient, and generally more affordable than larger vehicles. | Can lack the cargo space and versatility of SUVs/crossovers. | $18,000 – $60,000 |

| Truck (Lorry) | Large vehicles that are primarily used for transport of goods and materials. | High payload capacity, durable, ideal for heavy-duty tasks. | Generally not fuel-efficient, larger sizes can be difficult to maneuver. | $25,000 – $70,000 |

| Wagon (Hatchback) | Compact cars with a rear hatch door combining utility and efficiency. | Fuel-efficient, easier to maneuver, versatile space. | Smaller than SUVs, less towing capacity. | $15,000 – $40,000 |

| Coupe | Two-door car, often sporty, combining style and performance. | Sporty, stylish, often with better performance than sedans. | Less practical for daily use, limited passenger/cargo space. | $20,000 – $100,000+ |

| Convertible | Car with a retractable roof that offers an open-air driving experience. | Fun driving experience, stylish, good for sunny weather. | They are not practical in bad weather and often have less internal space. | $25,000 – $100,000+ |

| Sports Car (Roadster) | High-performance cars, often with two seats, focused on driving dynamics. | Exciting performance, sleek design, often with advanced technology. | Expensive, not practical for daily tasks, and higher maintenance costs. | $40,000 – $200,000+ |

| Luxury | Vehicles offering premium features, comfort, and performance. | High comfort level, advanced technology, superior craftsmanship. | Expensive to buy and maintain, and higher insurance costs. | $35,000 – $200,000+ |

| Electric | Powered entirely by electricity, known for efficiency and eco-friendliness. | Eco-friendly, low running costs, quieter driving experience. | Range limitations, long charging times, and higher initial cost. | $30,000 – $100,000+ |

| Hybrid | Combines a conventional engine with electric propulsion for efficiency. | Better fuel efficiency than conventional cars, reduced emissions. | Often more expensive than regular cars, complex technology. | $25,000 – $60,000 |

| Minivan | Designed for families, offering space and practicality for passengers. | Spacious, family-friendly, and versatile for cargo and passengers. | They are bulkier to drive and less stylish than other car types. | $25,000 – $50,000 |

| Van | Primarily used for transporting goods or people in bulk. | Spacious, practical for cargo or passenger transport, and versatile. | Large size, not as efficient as smaller vehicles, can be expensive. | $20,000 – $50,000 |

1. SUV

Sport Utility Vehicles or SUVs combine features of passenger cars with off-road capabilities. SUVs are recognizable for their high ground clearance and spacious interiors.

SUVs are versatile types of cars adept at handling various driving conditions, from city roads to rugged terrain. They are commonly used for journeys ranging from daily commutes, family transportation, recreational outings, and occasionally for towing and off-roading. The elevated seating of SUVs provides improved visibility to drivers and passengers alike. Moreover, with their large size, SUVs typically offer more passenger and cargo space than sedans or hatchbacks.

Most manufacturers offer SUVs in compact, mid-size, and full-size variants. Compact SUVs measure around 4.2 to 4.5 meters long and offer increased fuel efficiency, making them ideal for urban driving. Mid-size SUVs measure 4.5 to 4.8 meters and strike the balance between space and practicality. Compact SUVs are best suited for medium to large families. Full-size SUVs tend to measure over 4.8 meters, offer extensive interior space, and often have a towing capacity. Full-size SUVs capture the needs of larger families with diverse transportation needs.

What are the most notable truck manufacturers?

Below are the five main SUV manufacturers.

- Toyota: Toyota SUVs are known for reliability, and a broad range of SUV models, including the RAV4, Highlander, and Land Cruiser.

- Ford: Ford SUVs include popular models like the Ford Explorer and Ford Escape and are known for their performance, technology, and comfort.

- Honda: Honda SUVs are appreciated for their reliability, fuel efficiency, and family-friendly features. This includes popular models such as the CR-V and Pilot.

- BMW: BMW SUVs are a product of a luxury brand known for their high performance. SUVs like the X5 and X3 offer a combination of luxury, technology, and driving dynamics.

- Mercedes-Benz: Mercedes Benz is another luxury brand famous for its high-quality interiors and advanced technology in SUV models like the GLE and GLC.

Toyota SUVs

Toyota SUVs distinguish themselves through their reputation for reliability and durability. They offer a balance of off-road capability and on-road comfort, making them versatile for various driving needs. The Toyota brand is synonymous with safety, evidenced by its pedestrian detection, automatic high beams, advanced airbag system, blind spot monitor, backup camera, and Star Safety System enhancing stability and braking performance. Toyota is a leading maker of hybrid SUVs, with options available for the RAV4, Highlander, and Venza.

The main Toyota SUV models are listed below.

- Toyota RAV4: Known for its fuel efficiency and spacious interior, the RAV4 is a versatile and reliable compact SUV.

- Toyota Highlander: The Highlander stands out for its family-friendly spaciousness, strong safety features, and smooth ride.

- Toyota 4Runner: A rugged and durable SUV, the 4Runner excels in off-road capability and has a high towing capacity.

- Toyota C-HR: The C-HR is a stylish, compact crossover with a distinctive design and advanced safety technology.

- Toyota Land Cruiser: Renowned for its luxury, off-road prowess, and long-lasting durability, the Land Cruiser is a premium full-size SUV.

Ford SUVs

Ford SUVs stand out for their combination of robust performance, innovative technology, and affordability. These SUVs offer strong engine performance and towing capabilities, appealing to those who need both power and utility. Ford’s commitment to utilizing advancing technology is evident in their investment in driver-assistance features to enhance the driving experience.

The primary Ford SUV models are listed below.

- Ford Explorer: The Explorer offers a powerful engine lineup, ample cargo space, and advanced technology features.

- Ford Escape: Known for its agile handling and fuel-efficient engine options, the Escape is a compact SUV ideal for city driving.

- Ford Edge: The Edge stands out with its spacious cabin, smooth ride, and cutting-edge infotainment system.

- Ford Expedition: A large SUV known for its spacious and luxurious interior, powerful towing capacity, and robust engine.

- Ford EcoSport: A compact crossover that offers an elevated seating position, user-friendly technology, and an efficient engine.

Honda SUVs

Honda SUVs are known for their reliability, fuel efficiency, and practical design. They offer well-crafted interiors with ample space, making them the ideal type of car for families and daily commuting. Honda focuses on safety with features like the collision mitigation braking system, Advanced Compatibility Engineering (ACE) body structures, and Vehicle Stability Assist (VSA). Honda’s reputation for durable and long-lasting vehicles also ensures their SUVs retain a strong resale value, making them a popular choice among second-hand market consumers.

The main Honda SUV models are listed below.

- Honda CR-V: The CR-V is praised for its spacious and comfortable interior, fuel efficiency, and strong reliability record.

- Honda Pilot: A midsize SUV known for its spacious third-row seating, smooth ride, and practicality for families.

- Honda HR-V: The HR-V stands out with its compact size, versatile cargo space, and excellent fuel economy.

- Honda Passport: Offers a comfortable ride, ample cabin space, and robust off-road capability in a midsize package.

- Honda Element: Known for its unique boxy design, versatile and spacious interior, and easy-to-clean surfaces.

BMW SUVs

BMW SUVs distinguish themselves from the competition with a focus on luxurious interiors, advanced technology, and a strong emphasis on driving dynamics. Renowned for their sporty handling and powerful engines, BMW SUVs blend the characteristics wanted in traditional SUVs with the more desirable performance characteristics of sportier cars. Models like the BMW X5 and X3 showcase this blend of performance and luxury and demonstrate everything that sets BMW SUVs apart.

BMW SUVs are marketed in X models, which ascend in value according to their size and luxury.

- BMW X1: A luxury subcompact SUV offering sporty handling, a high-quality interior, and a strong engine.

- BMW X2: Stands out for its athletic performance, sleek design, and premium interior in the subcompact SUV segment.

- BMW X3: A compact luxury SUV known for its dynamic performance, high-quality cabin, and advanced technology features.

- BMW X4: Combines sporty handling with a coupe-like design and luxurious interior in a compact SUV form.

- BMW X5: A midsize luxury SUV that excels in performance, comfort, and advanced technology features.

- BMW X6: Offers a unique coupe-like design, powerful engine options, and a luxurious, tech-filled interior.

- BMW X7: The largest in the lineup, known for its spacious and opulent interior, powerful performance, and advanced technology.

Mercedes-Benz SUVs

Mercedes-Benz SUVs are renowned for their combination of luxury, advanced technology, and performance. Mercedes SUVs set themselves apart with high-end interiors made from premium materials and meticulous craftsmanship. Mercedes-Benz SUVs, such as the GLC and GLE, lead the way in incorporating innovative technology such as advanced driver assistance systems and state-of-the-art Mercedes-Benz User Experience (MBUX) suite of vehicle infotainment. Additionally, Mercedes SUVs offer a range of powerful engine options, providing a positive driving experience despite the vehicle’s size.

The core Mercedes-Benz SUV models are listed below.

- Mercedes-Benz GLC: A compact luxury SUV known for its elegant interior, smooth ride, and advanced tech features.

- Mercedes-Benz GLE: Offers a balance of luxury, comfort, and technology in a midsize SUV, with a spacious and refined interior.

- Mercedes-Benz GLA: A subcompact luxury crossover that stands out for its agile handling, premium interior, and efficient performance.

- Mercedes-Benz G-Class: Renowned for its iconic design, unparalleled off-road capability, and luxurious interior.

2. Crossover

Crossovers are a fusion of SUVs and traditional passenger cars. Crossovers typically feature unibody construction, which is a design derived from passenger cars, contributing to a lighter weight and improved fuel efficiency compared to SUVs, which have a body-on-frame construction. Crossovers come in various sizes, ranging from compact to mid-size, and offer the versatility and spaciousness of SUVs while maintaining a more compact carbon footprint suitable for urban driving.

Crossovers are distinguishable from other car types thanks to their combination of higher ground clearance combined with a more car-like driving experience. Crossovers typically have better handling and offer a smoother ride than larger SUVs. This makes Crossovers the ideal car type for families and individuals looking for practicality and space but is not willing to surrender heightened control of maneuverability. Many manufacturers design their crossovers to include features like flexible seating arrangements and ample cargo space. Modern crossover models offer advanced safety and technology features, catering to a wide range of driving needs and lifestyles.

What are the most notable crossover manufacturers?

The five main Crossover manufacturers are listed below.

- Toyota: Toyota’s crossovers, like the RAV4, are known for their reliability, fuel efficiency, and family-friendly designs.

- Honda: Honda offers crossovers such as the CR-V, which are celebrated for their practicality, comfort, and advanced safety features.

- Mazda: Mazda’s crossovers, including the CX-5, stand out for their sleek design, engaging driving experience, and premium interiors.

- Hyundai: Hyundai, with models like the Tucson, provides a blend of value, sophisticated design, and extensive technology features.

- Subaru: Subaru’s crossovers, including the Forester, are renowned for their all-wheel-drive capabilities and strong emphasis on safety and durability.

Toyota crossovers

Toyota crossovers, such as the RAV4, Highlander, and C-HR, are well-regarded for their blend of reliability and practicality. The Highlander offers spaciousness and comfort, ideal for families, while the C-HR stands out for its unique style and compact design, which make it suitable for urban environments. All Toyota crossover models exemplify Toyota’s commitment to safety, with features like the Toyota Safety Sense (TSS) suite showcasing the brand’s focus on producing vehicles that are both reliable and adaptable to the different rigors of daily life.

The main Toyota Crossover vehicles are listed below.

- Toyota RAV4: A popular compact crossover known for its reliability, fuel efficiency, and spacious interior.

- Toyota Highlander: Ideal for families, the Highlander offers ample space, a smooth ride, and strong safety features.

- Toyota C-HR: A stylish and compact crossover with unique design elements and advanced safety technologies.

- Toyota Venza: A midsize crossover known for its sleek styling, hybrid efficiency, and upscale interior.

- Toyota Corolla Cross: Combines the reliability of the Corolla with the versatility of a crossover, offering compact efficiency and practicality.

Honda crossovers

Honda crossovers, notably the CR-V, HR-V, and Pilot, distinguish themselves from their competitors through a focus on practicality, comfort, and advanced safety. The CR-V, known for its spacious interior and fuel efficiency, is ideal for families and everyday commuting. The HR-V appeals with its compact size and versatile cabin space, making it suitable for city driving. The larger Pilot offers three-row seating and robust performance, catering to those needing more passenger seating and storage space. Honda is a manufacturer committed to driver and passenger safety, as evidenced by the inclusion of features like the Honda Sensing suite in their crossover fleet.

The most popular Honda crossovers are listed below.

- Honda CR-V: Praised for its roomy and comfortable interior, fuel efficiency, and excellent safety ratings.

- Honda HR-V: A compact crossover with versatile cargo space, efficient performance, and a practical design.

- Honda Pilot: A family-friendly midsize crossover known for its spacious seating, smooth handling, and robust features.

- Honda Passport: Offers a blend of off-road capability and comfort with a spacious cabin and powerful performance.

- Honda Element: Noted for its unique boxy design, spacious and flexible interior, and easy-to-clean surfaces.

Subaru crossovers

Subaru crossovers, such as the Forester, Outback, and Crosstrek, are renowned for their rugged all-wheel-drive system, which enhances their off-road and adverse weather capabilities. The Forester offers a blend of safety, space, and visibility, making it a family-friendly option while the Outback stands out for its wagon-like design and off-road ability, appealing to outdoor enthusiasts. The smaller and more agile Crosstrek, is well-suited for both urban and adventure use providing everything a fun-loving motorist could need. Subaru crossovers all embody a safety-conscious mindset, as evidenced by the EyeSight Driver-Assist technology.

The five best-known Subaru crossover models are listed below.

- Subaru Outback: A wagon-like crossover known for its standard all-wheel drive, spacious interior, and off-road capability.

- Subaru Forester: Stands out for its standard all-wheel drive, roomy interior, and excellent visibility.

- Subaru Crosstrek: A compact crossover offering a balanced ride, efficient performance, and rugged styling.

- Subaru Ascent: Subaru’s largest crossover, known for its spacious third-row seating, safety features, and all-wheel drive.

- Subaru XV Crosstrek Hybrid: A hybrid crossover combining Subaru’s rugged styling with improved fuel efficiency.

Mazda crossovers

Mazda crossovers, such as the CX-5, CX-30, and CX-9, stand out for their emphasis on driving dynamics and elegant design. The CX-5 is known for its engaging driving experience and upscale interior, setting a high standard in its class, while the CX-30 offers a compact size with a premium feel, making it the ideal car type for city driving. The larger CX-9 provides a more spacious interior with a focus on luxury and the needs of larger families. Mazda crossovers offer a unique blend of performance, style, and build quality according to the company’s Kodo design language, which translates to “soul of motion” in Japanese. As a result, these vehicles have a consistent brand identity defined by simplicity, elegance, and human-centric design.

The core five Mazda Crossovers are listed below.

- Mazda CX-5: Known for its sporty driving dynamics, upscale interior, and attractive design.

- Mazda CX-30: A subcompact crossover offering a premium interior, agile handling, and modern technology.

- Mazda CX-9: A family-friendly midsize crossover with a luxurious interior, smooth ride, and engaging performance.

- Mazda CX-3: A small crossover known for its sharp handling, stylish design, and compact efficiency.

- Mazda CX-50: A new addition offering rugged styling, off-road capability, and a comfortable, tech-rich interior.

Hyundai crossovers

Hyundai crossovers, including models like the Tucson, Santa Fe, and Kona, stand out for their innovative design, and comprehensive technology features. The Tucson offers a balance of style, space, and technology, appealing to a wide range of buyers while the Santa Fe provides a larger and more family-oriented crossover option with ample space and comfort along with Hyundai’s advanced safety features. Conversely, the Kona offers a more compact option that stands out for its style and high-grade efficiency.

The primary Hyundai Crossovers are listed below.

- Hyundai Tucson: A compact crossover with a modern design, spacious interior, and a range of tech features.

- Hyundai Kona: A subcompact crossover known for its distinctive style, agile handling, and efficient engine options.

- Hyundai Santa Fe: A midsize crossover offering a spacious and upscale interior, smooth ride, and advanced safety tech.

- Hyundai Palisade: Hyundai’s largest crossover, known for its roomy interior, luxury features, and smooth ride.

- Hyundai Venue: A small, urban-focused crossover with a compact footprint, efficient performance, and modern amenities.

3. Sedan

Sedans are a type of car that features a distinct three-box configuration composed of separate sections for the engine, passengers, and cargo. Sedans are characterized by a fixed roof, four doors, and a traditional trunk, which offers a strict separation between the passenger and luggage compartments. Sedans are available in various sizes, ranging from compact models with high efficiency that are ideal for city driving to mid-size and full-size sedans that provide more interior space, comfort, and luxury.

Larger sedans often include enhanced features such as more powerful engines, advanced technology, and premium materials. Compared to SUVs, sedans generally have a lower ground clearance and an enhanced aerodynamic profile. Sedans provide better fuel efficiency and a smoother ride to larger car types like SUVs and crossovers. Unlike hatchbacks, sedans have a dedicated trunk, providing a more secure and separate cargo space. A sedan’s base design is geared towards providing a comfortable and practical driving experience, making it a popular choice for both daily commuting and long-distance travel.

What are the most notable sedan manufacturers?

Below are the five most respected sedan manufacturers.

- Toyota: Renowned for durability and efficiency, Toyota sedans like the Camry and Corolla cater to those seeking reliability and value.

- Honda: Honda sedans, such as the Accord and Civic, combine practicality with a touch of sportiness, appealing to a wide range of drivers.

- Mercedes-Benz: Offering luxury and sophistication, Mercedes-Benz sedans like the C-Class and E-Class are known for their advanced features and elegant design.

- BMW: BMW sedans, including the 3 Series and 5 Series, emphasize a sporty driving experience with a focus on performance and technology.

- Audi: Audi sedans, such as the A4 and A6, stand out for their sleek design, all-wheel drive capabilities, and high-quality interiors, offering a blend of performance and luxury.

Toyota sedans

Toyota sedans, such as the Camry and Corolla, are distinguished by their exceptional reliability and value for money. The Camry is known for its comfortable ride and spacious interior, offering a balance of efficiency and performance. The Corolla, however, stands out for its compact size, fuel efficiency, and affordability, making it a popular choice for city driving and everyday commuting. Many Toyota sedans come with the Toyota’s Safety Sense package, enhancing their appeal as safe, family-friendly cars.

The core Toyota sedans are listed below.

- Toyota Camry: A midsize sedan known for its reliability, comfortable ride, and fuel-efficient engine options.

- Toyota Corolla: A compact sedan offering great fuel economy, a reliable track record, and advanced safety features.

- Toyota Avalon: A large sedan known for its spacious and luxurious interior, smooth ride, and strong performance.

- Toyota Prius: The iconic hybrid sedan famous for its exceptional fuel efficiency and eco-friendly technology.

- Toyota Yaris: A subcompact sedan offering an affordable price, efficient performance, and easy maneuverability.

Honda sedans

Honda sedans, such as the Accord and Civic, stand out for their blend of practicality, fuel efficiency, and engaging driving experience. The Accord is well-known for its spacious interior, advanced safety features, and smooth ride, making it a favorite in the mid-size sedan category. The Honda Civic, with its compact design, offers the winning combination of agility and efficiency, making it the ideal type of car for urban environments. All Honda sedans are equipped with Honda Sense, a suite of safety and driver-assist technologies that cements their reputation as safe vehicles.

Below is a list of the primary Honda sedans.

- Honda Accord: A popular midsize sedan known for its spacious cabin, efficient performance, and advanced safety tech.

- Honda Civic: A compact sedan that stands out for its sporty performance, fuel efficiency, and modern interior.

- Honda Insight: A hybrid sedan offering a blend of fuel efficiency, sleek styling, and a comfortable ride.

- Honda Clarity: Available in hybrid and electric variants, known for its eco-friendly performance and spacious interior.

- Honda City: A subcompact sedan noted for its practicality, fuel efficiency, and comfortable cabin.

Mercedes-Benz sedans

Mercedes-Benz sedans, including models like the C-Class and E-Class, are distinguished by their luxury, advanced technology, and refined performance. The C-Class offers a high-end interior mixed with innovative technology, catering to those who want a luxury ride in an everyday form. The E-Class, known for its comfort and sophisticated driver assistance systems, appeals to drivers looking for a blend of luxury and practicality.

The top five Mercedes-Benz sedans are as follows.

- Mercedes-Benz C-Class: A compact luxury sedan offering a blend of performance, luxury, and advanced technology.

- Mercedes-Benz E-Class: A midsize luxury sedan known for its sophisticated interior, smooth ride, and cutting-edge tech.

- Mercedes-Benz S-Class: The flagship luxury sedan offering opulent comfort, advanced technology, and powerful performance.

- Mercedes-Benz A-Class: A compact sedan with a modern interior, efficient performance, and high-tech features.

- Mercedes-Benz CLS-Class: A luxury sedan with a coupe-like design, powerful engines, and a premium interior.

BMW sedans

BMW sedans, notably the 3 Series and 5 Series, are renowned for their sporty handling and performance-oriented driving experience. The 3 Series, popular for its agile handling and powerful engine options, appeals to those who want to experience a dynamic driving experience, while the 5 Series offers a balance of luxury, performance, and technology. BMW sedans emphasize the company’s commitment to creating the ‘Ultimate Driving Machine,’ with their focus on delivering a memorable and luxurious driving experience.

The most popular BMW sedans are listed below.

- BMW 3 Series: A compact executive sedan known for its sporty handling, refined interior, and advanced tech.

- BMW 5 Series: A midsize luxury sedan offering a perfect blend of performance, comfort, and technology.

- BMW 7 Series: BMW’s flagship luxury sedan, known for its spacious and opulent interior and advanced technology.

- BMW 4 Series Gran Coupe: Combines the sportiness of a coupe with the practicality of a sedan in a sleek design.

- BMW 2 Series Gran Coupe: A compact sedan with a sporty edge, modern styling, and advanced technology features.

Audi sedans

Audi sedans, such as the A4 and A6, distinguish themselves with sophisticated design, advanced technology, and Quattro all-wheel-drive system. The A4 is well-regarded for its refined interior, cutting-edge infotainment, and performance, making it a suitable choice for daily commuting and more adventurous driving experiences. The A6 offers a blend of luxury and innovation, with a spacious cabin and a suite of driver-assistance technologies.

The best Audi sedans are as follows.

- Audi A4: A compact luxury sedan known for its refined interior, balanced performance, and advanced technology.

- Audi A6: A midsize luxury sedan offering a blend of comfort, technology, and performance.

- Audi A8: Audi’s flagship luxury sedan, known for its advanced technology, luxurious amenities, and powerful engines.

- Audi A3: A compact luxury sedan with a stylish design, agile handling, and high-quality interior.

- Audi S and RS Models: High-performance variants of Audi sedans, offering enhanced power, sportier styling, and advanced driving dynamics.

4. Truck (Lorry)

Trucks are a robust type of vehicle designed for transporting goods and materials over various distances. Trucks come in various sizes and capacities, ranging from smaller, medium-duty trucks ideal for local deliveries and lighter loads to large, heavy-duty trucks built for long-haul transport and substantial loads. Distinguished by their powerful (typically diesel) engines and sturdy construction, trucks are engineered to handle the heavy demands of life on the road.

Truck designs vary from box trucks and flatbeds to refrigerated and tanker trucks, each one tailored for specific types of cargo and transportation needs. Unlike smaller commercial vehicles, trucks are essential for the efficient movement of bulk goods, and their usage is driven more by need than preference.

What are the most notable truck manufacturers?

The five top truck manufacturers are listed below.

- Volvo: Volvo trucks are known for their reliability, fuel efficiency, and advanced safety features.

- DAF: DAF offers a range of trucks renowned for their durability, low operational costs, and driver comfort.

- Scania: Scania trucks stand out for their strong performance, sustainability focus, and innovative technology.

- Mercedes-Benz: Mercedes-Benz trucks are recognized for their high quality, technological advancements, and versatility in various applications.

- MAN: MAN trucks are notable for their efficiency, robust engineering, and a wide range of models catering to different transport needs.

Volvo trucks

Volvo trucks stand out for their strong emphasis on safety, environmental sustainability, and driver comfort. Notable models like the Volvo FH and Volvo FM come with advanced safety features, including driver assistance systems for enhanced road safety. Volvo’s commitment to sustainability is evident in its efforts to develop more fuel-efficient and lower-emission engines. Additionally, Volvo trucks are known for their ergonomic design and comfortable cabs, which improve the driving experience, especially for long-haul journeys.

The most notable Volvo truck models are listed below.

- Volvo FH: A long-haul truck known for its high performance, fuel efficiency, and advanced safety features.

- Volvo FM: Versatile and reliable, the FM is designed for regional transport and offers excellent maneuverability.

- Volvo FMX: Built for tough construction jobs, the FMX excels in durability, robustness, and off-road capability.

- Volvo FE: Ideal for city and regional operations, the FE is known for its agility, efficiency, and low emissions.

- Volvo FL: A compact truck designed for urban environments, offering great visibility, maneuverability, and efficiency.

Scania trucks

Scania trucks are renowned for their high performance, durability, and the company’s focus on sustainability. Models like the Scania R-Series and Scania S-Series boast powerful engines designed for both efficiency and reliability, making them suitable for a range of heavy-duty operations. Scania’s commitment to sustainability is evident in its investment in alternative fuel technology and continued pursuit of reduced emissions. Scania trucks are appreciated for their modular design, which offers easy customizations to a detailed level for each specific transport need.

The main Scania truck models are as follows.

- Scania R-Series: A long-distance truck known for its robustness, comfort, and powerful engine options.

- Scania S-Series: Offers a spacious and luxurious cabin, high efficiency, and is designed for long-haul operations.

- Scania G-Series: A versatile truck suitable for a wide range of applications, known for its comfort and reliability.

- Scania P-Series: Designed for urban and regional operations, the P-Series is known for its maneuverability and efficiency.

- Scania L-Series: A low-entry cab truck ideal for urban environments, focusing on visibility and safety.

DAF trucks

DAF trucks are distinguished by their economic efficiency, driver comfort, and reliability. Models like the DAF XF and DAF CF are popular among drivers for their fuel-efficient engines. They are also a favorite with business owners thanks to their lower operational costs via fuel efficiency, predictive maintenance systems, and overall build quality. DAF trucks also focus on driver comfort, with well-designed cabs that offer a comfortable driving environment, which is an often overlooked necessity for those driving long-haul journeys.

The core models of the DAF fleet are as follows.

- DAF XF: A flagship long-haul truck known for its fuel efficiency, powerful performance, and driver comfort.

- DAF CF: Versatile and efficient, the CF is suitable for a wide range of transport applications.

- DAF LF: A lightweight truck designed for city and regional distribution, known for its agility and low operating costs.

- DAF XG and XG+: Represents a new generation of trucks with enhanced space, luxury, and efficiency for long hauls.

- DAF XD: A new model focusing on distribution transport, combining efficiency, maneuverability, and comfort.

Mercedes-Benz trucks

Mercedes-Benz trucks are known for their quality and technological advancements. Models like the Mercedes-Benz Actros and Arocs come with advanced driver assistance systems, which not only enhance safety but also increase efficiency. Mercedes-Benz trucks are also recognized for their powerful engines and robust construction, making them the ideal truck choice for a wide range of transport needs. Mercedes-Benz trucks continually integrate innovative technologies, such as connectivity features and telematics, which work to improve overall fleet management and operational efficiency rather than just on a truck-by-truck basis.

The front-line Mercedes-Benz trucks are listed below.

- Mercedes Actros: Known for its innovative technology, fuel efficiency, and comfort, ideal for long-distance haulage.

- Mercedes Arocs: Built for construction applications, the Arocs excels in strength, durability, and off-road capability.

- Mercedes Antos: Designed for heavy-duty distribution, the Antos is known for its efficiency and versatility.

- Mercedes Atego: A medium-duty truck ideal for light distribution with great maneuverability and reliability.

- Mercedes Econic: An urban-focused truck with a low-entry cab, emphasizing safety and environmental friendliness.

MAN trucks

MAN trucks distinguish themselves through their focus on fuel efficiency and robust engineering. Models like the MAN TGX and TGS are known for their highly efficient engines, which help reduce fuel consumption and lower overall operating costs. MAN trucks also feature strong build quality, making them reliable when faced with the rigors of heavy-duty transportation. Additionally, MAN offers a diverse range of trucks, catering to the variety of needs seen in the transport and logistics industry.

The main MAN truck models are as follows.

- MAN TGX: A high-performance truck for long-haul transport, offering efficiency, comfort, and advanced technology.

- MAN TGS: A robust and reliable truck designed for a variety of applications, from construction to heavy-duty transport.

- MAN TGM: Suitable for medium to heavy-duty distribution, the TGM is known for its versatility and efficiency.

- MAN TGL: A light truck perfect for urban and short-haul transport, offering high payload capacity and agility.

- MAN TG3: A new range focusing on efficiency, comfort, and advanced digital solutions for various transport needs.

5. Wagon (Hatchback)

Hatchbacks are a popular type of car known for their distinctive rear door that swings upward, leading directly into designated trunk space. Hatchbacks feature a two-box configuration, with a more seamless integration of passenger and cargo space compared to sedans. Hatchbacks range from small, compact models, ideal for city driving and easy parking, to larger versions that provide the necessary space and flexibility needed by families.

The key advantage hatchbacks hold over other car types lies in their flexible and accessible trunk. This accessibility, combined with typically foldable rear seats, creates a versatile interior that can adapt to varying storage needs. Hatchbacks are often preferred for their practicality in urban environments, as they offer a good balance of compact exterior dimensions and interior space. A hatchback’s design makes them particularly suitable for drivers who need the maneuverability of a small car with the utility of a larger cargo area.

What are the most notable hatchback manufacturers?

The five premier hatchback brands are listed below.

- Volkswagen: Volkswagen makes well-engineered hatchbacks like the Golf, known for their quality and performance.

- Ford: Ford’s hatchbacks, such as the Fiesta, are recognized for their driving dynamics and practicality.

- Honda: Honda hatchbacks, including the Civic Hatchback, combine efficiency with a sporty design.

- Toyota: Known for reliability, Toyota’s hatchbacks like the Corolla offer practicality and efficiency.

- Hyundai: Hyundai’s hatchbacks, such as the i30, are appreciated for their value, features, and design.

Volkswagen hatchbacks

Volkswagen hatchbacks, such as the iconic Golf and the Polo, are renowned for their build quality, practicality, and driving performance. The Golf, in particular, is renowned for offering a comfortable ride, spacious interior, and a range of efficient engine options. The smaller Polo is often lauded for its maneuverability and efficient use of space, making it a great car type and model for urban driving. Volkswagen maximizes the utility of its hatchbacks without compromising the quality of life for the driver.

The best-known Volkswagen hatchbacks are listed below.

- Volkswagen Golf: A compact hatchback known for its versatile design, comfortable ride, and efficient performance.

- Volkswagen Polo: A small hatchback offering a refined ride, efficient engines, and advanced safety features.

- Volkswagen GTI: A performance-oriented version of the Golf, known for its sporty handling and powerful engine.

- Volkswagen ID.3: An all-electric hatchback known for its innovative technology, range efficiency, and modern design.

- Volkswagen Beetle: A classic and iconic compact car known for its unique design and fun driving experience.

Ford hatchbacks

Ford hatchbacks, like the Fiesta and Focus, stand out for their engaging driving dynamics and practical design. The Fiesta is both affordable and agile, making it an ideal solution for navigating urban environments. The Focus, in comparison, offers a more spacious interior as well as a robust suite of driver-assist features like pre-collision detection, blind spot radar, and lane-keeping assistance. Ford hatchbacks are not luxury vehicles, but they do offer a pleasant daily driving experience, relatively low maintenance costs, and excellent fuel economy.

Below is a list of the core hatchbacks in the Ford fleet.

- Ford Fiesta: A compact car celebrated for its agile handling, efficient engines, and modern tech features.

- Ford Focus: A small family car known for its balanced ride, spacious interior, and advanced technology.

- Ford Mustang Mach-E: An all-electric SUV combining Mustang’s performance heritage with eco-friendly efficiency.

- Ford EcoSport: A compact crossover offering an elevated driving position, practicality, and versatile use.

- Ford Puma: A small crossover known for its sporty dynamics, efficient engine options, and smart technology.

Honda hatchbacks

Honda hatchbacks, particularly the Honda Civic Hatchback and Honda Fit, are known for their efficient use of space, reliability, and fuel efficiency. The Civic Hatchback offers a sportier design, boasting sufficient interior space and a balance of performance and efficiency. The smaller Fit stands out for its “Magic Seat” system, which offers four folding configurations that allow drivers to maximize limited interior cargo space.

The primary Honda hatchback models are as follows.

- Honda Civic Hatchback: A compact car offering sporty handling, a spacious interior, and advanced safety tech.

- Honda Fit (Jazz): A subcompact hatchback known for its versatile interior, fuel efficiency, and compact size.

- Honda HR-V: A subcompact crossover combining the utility of an SUV with the efficiency of a smaller car.

- Honda CR-Z: A hybrid electric vehicle known for its sporty design and environmentally friendly performance.

- Honda Civic Type R: A high-performance hatchback known for its powerful engine, aggressive styling, and sporty handling,

Toyota hatchbacks

Toyota hatchbacks, including the Toyota Corolla Hatchback and Yaris, are renowned for their reliability, fuel efficiency, and practicality. The Corolla Hatchback offers a spacious and comfortable interior, along with advanced safety features without sacrificing the overall driving experience. The smaller and more affordable Yaris is appreciated for its compact design and high efficiency, which makes it a great choice for city living.

The top five Toyota hatchbacks are listed below.’

- Toyota Corolla Hatchback: A compact car offering a stylish design, efficient performance, and advanced safety features.

- Toyota Yaris: A subcompact car known for its affordability, fuel efficiency, and easy maneuverability.

- Toyota Prius: The iconic hybrid car known for its excellent fuel economy and eco-friendly technology.

- Toyota C-HR: A compact crossover with a distinctive style, advanced safety features, and a comfortable ride.

- Toyota GR Yaris: A high-performance version of the Yaris, designed for agility, speed, and an engaging driving experience.

Hyundai hatchbacks

Hyundai hatchbacks, such as the Hyundai i30 and Veloster, stand out for their combination of value, modern design, and comprehensive feature sets. The i30 is appreciated for its balance of comfort, style, and technology and is the ideal all-rounded in the hatchback car type. The Veloster, with its unique three-door configuration, caters to those who want a more distinctive vehicle with a sporty feel.

The main Hyundai hatchbacks are as follows.

- Hyundai i20: A compact car offering a stylish design, efficient performance, and a comfortable interior.

- Hyundai Veloster: A unique three-door hatchback known for its sporty design and engaging driving experience.

- Hyundai Kona: A small crossover SUV with a bold design, efficient engines, and versatile performance.

- Hyundai Elantra GT: A compact hatchback combining a spacious interior with sporty handling and modern features.

6. Coupe

Coupes are distinguished by their sleek, sporty two-door body design that prioritizes aesthetics and performance. Coupes typically feature a shorter wheelbase and a more compact frame compared to sedans, with a sloping rear roofline that gives them a dynamic appearance. They are designed for drivers who value a stylish and exciting driving experience. The smaller size of coupes means they offer an intimate driving environment, which is a hallmark of this type of car.

Coupes vary in size from smaller, more agile models with a strong emphasis on handling to larger, luxury-oriented coupes with powerful engines and advanced features. Despite their varying sizes, coupes consistently maintain a focus on design and performance. While coupes generally have room for two to four passengers, the emphasis is on driver enjoyment and aesthetic appeal rather than practicality or utility. This makes coupes a more prevalent choice among car enthusiasts rather than a car for the family or even daily commutes.

What are the most notable coupe manufacturers?

Below are the five main coupe manufacturers.

- BMW: BMW coupes are known for dynamic handling and elegant design in models like the 4 Series.

- Mercedes-Benz: Mercedes offers luxury coupes such as the C-Class Coupe, focusing on sophistication and performance.

- Audi: Audi’s coupes, including the A5, combine sleek design with cutting-edge technology.

- Porsche: Porsche coupes are celebrated for iconic style and exceptional driving dynamics, especially in the Porsche 911.

- Chevrolet: Chevrolet coupes merge classic American muscle with modern performance in coupes like the Camaro.

BMW coupes

BMW coupes, such as the 4 Series and 2 Series, stand out for their blend of sporty dynamics, elegance, and advanced technological features. The 4 Series Coupe balances luxury and performance with its refined handling and powerful engines. The 2 Series Coupe is a more compact model and is well-praised for its agility and engaging driving experience.

The five primary BMW coupe models are as follows.

- BMW 2 Series Coupe: A compact coupe known for its sporty handling, stylish design, and engaging driving experience.

- BMW 3 Series Coupe: Offers a balance of performance and luxury in a compact coupe form, with sleek styling and a comfortable interior.

- BMW 4 Series Coupe: A luxury coupe combining elegant design, advanced technology, and dynamic driving performance.

- BMW 8 Series Coupe: A grand tourer offering a blend of luxury, performance, and cutting-edge technology in a sleek design.

- BMW M4: A high-performance version of the 4 Series, known for its powerful engine, sporty handling, and aggressive styling.

- BMW i8: A plug-in hybrid sports car offering futuristic design, eco-friendly performance, and innovative technology.

Mercedes-Benz coupes

Mercedes-Benz coupes, including the C-Class Coupe and E-Class Coupe, are distinguished by their luxurious interiors, advanced technology, and elegant bodywork. The C-Class Coupe offers a blend of comfort and sportiness, with a focus on high-quality materials and a smooth driving experience. The E-Class Coupe expands on this with added space and refined luxury features.

The top five Mercedes-Benz coupes are listed below.

- Mercedes-Benz C-Class Coupe: A compact luxury coupe offering a stylish design, sporty performance, and advanced features.

- Mercedes-Benz E-Class Coupe: A midsize luxury coupe known for its elegant design, comfortable ride, and high-quality interior.

- Mercedes-Benz S-Class Coupe: A large luxury coupe offering a blend of opulence, advanced technology, and powerful performance.

- Mercedes-Benz CLA Coupe: A compact four-door coupe known for its sleek styling, sporty dynamics, and modern technology.

- Mercedes-Benz AMG GT: A high-performance sports car with a striking design, powerful engines, and a luxurious interior.

Audi coupes

Audi coupes, such as the Audi A5 and TT, stand out for their modern design, advanced technology, and the Quattro all-wheel-drive system. The A5 Coupe is known for its sleek styling, luxurious interior, and impressive technical suite. The Audi TT has a distinctive design and sporty character. It provides a much more dynamic driving experience than some of their other models.

Below are the five premier Audi coupes.

- Audi TT Coupe: A compact sports coupe known for its iconic design, agile handling, and premium interior.

- Audi A5 Coupe: A luxury coupe offering a balance of style, performance, and advanced technology.

- Audi R8 Coupe: A high-performance supercar offering thrilling performance, advanced technology, and a striking design.

- Audi S and RS Models: Performance-oriented versions of Audi coupes, featuring enhanced power and sportier styling.

- Audi A3 Coupe: A compact luxury coupe offering a sporty drive, advanced features, and a high-quality interior.

Porsche coupes

Porsche coupes, particularly the iconic 911 and the 718 Cayman, are renowned for their exceptional performance and unmistakable design. The 911 offers a unique driving experience thanks to its rear-engine configuration, which blends sports car agility with everyday usability. The 718 Cayman is celebrated for its mid-engine balance, precision handling, and driver-focused cockpit. Porsche showcases their unwavering commitment to high-performance engineering in every coupe they build.

The five core coupes in the Porsche fleet are as follows.

- Porsche 911: An iconic sports car celebrated for its performance, handling, and timeless design.

- Porsche 718 Cayman: A mid-engine sports coupe known for its precise handling, sleek design, and engaging drive.

- Porsche Panamera: A luxury sports coupe offering spaciousness, sophisticated design, and high performance.

- Porsche Taycan: An all-electric sports car combining performance, innovation, and luxury.

- Porsche 911 GT3 RS: A high-performance version of the 911, optimized for track performance with a focus on speed and handling.

Chevrolet coupes

Chevrolet coupes, like the Camaro and Corvette, blend the American muscle car heritage with modern performance. The Camaro offers a range of powerful engine options and a design that pays homage to its classic muscle car roots. The Corvette, particularly the mid-engine model, represents a leap in performance and handling that now rivals European sports cars.

The main Chevrolet coupes are listed below.

- Chevrolet Corvette: An iconic American sports car known for its powerful performance, sleek design, and advanced technology.

- Chevrolet Camaro: A muscle car offering strong performance, aggressive styling, and a range of powerful engines.

- Chevrolet Bolt EV: An all-electric car offering efficiency, modern technology, and a compact design.

- Chevrolet SS: A performance sedan known for its powerful V8 engine, sporty handling, and comfortable interior.

- Chevrolet Cobalt SS: A compact sports coupe offering an affordable performance package with a turbocharged engine and sport-tuned suspension.

7. Convertible

Convertibles, also known as cabriolets, are one of the more distinctive types of car thanks to their retractable roofs, which allow them to transform from enclosed to open-air vehicles. A convertible’s design caters to drivers seeking the pleasure of open-top driving, combined with the convenience of a closed roof for varying weather conditions. Convertibles are typically available in soft-top or hard-top designs, each offering its own distinctive advantages and disadvantages.

Convertibles vary in size from compact roadsters, with agile handling and a sporty look and feel, to larger luxury models with extra space and comfort for those who like to enjoy the drive. Unlike other car types, the primary appeal of convertibles lies in their prestige and the status statement they make. Convertibles offer a sense of freedom to drivers, allowing them to find greater enjoyment on the road. They are a type of car that is especially favored in areas with mild climates, where the open-top experience is truly enjoyable.

What are the most notable convertible manufacturers?

Below are the five top convertible manufacturers.

- Mercedes-Benz: Mercedes convertibles like the E-Class Cabriolet are known for their elegance and advanced technology, which produce a luxurious driving experience.

- BMW: BMW’s convertibles, such as the Z4, are celebrated for their sporty dynamics and premium interiors.

- Porsche: Porsche provides high-performance convertibles like the 911 Cabriolet, renowned for their exceptional driving experience.

- Audi: Audi’s convertibles, including the A5 Cabriolet, combine sleek design with sophisticated technology.

- Jaguar: Jaguar, with models like the F-TYPE Convertible, is known for their distinctive design and powerful performance.

Mercedes-Benz convertibles

Mercedes-Benz convertibles, such as the E-Class Cabriolet and SL Roadster, set themselves apart with advanced technology and refined performance. The E-Class Cabriolet offers a comfortable and elegant open-air driving experience, with cutting-edge safety features thrown into the mix. The SL Roadster is renowned for having a sportier feel that combines Mercedes-Benz’s traditional luxury with high-end performance.

The primary Mercedes-Benz convertibles are as follows.

- Mercedes-Benz SL-Class: A luxury roadster known for its elegant design, powerful performance, and advanced technology.

- Mercedes-Benz C-Class Cabriolet: Offers a blend of luxury and sportiness with a comfortable interior and efficient engines.

- Mercedes-Benz E-Class Cabriolet: A midsize convertible combining luxury, comfort, and advanced safety features.

- Mercedes-Benz S-Class Cabriolet: The pinnacle of luxury convertibles, offering opulence, advanced tech, and smooth performance.

- Mercedes-Benz AMG GT Roadster: A high-performance sports car known for its powerful engine, agile handling, and luxurious features.

BMW convertibles

BMW convertibles, like the Z4 Roadster and the 4 Series Convertible, are well-regarded for their sporty handling and exceptional overall driving experience. The Z4, a two-seater roadster, offers agile handling and a powerful engine, making it a favorite among convertible enthusiasts, particularly those who are looking for prioritized performance. The 4 Series Convertible combines the sportiness typical of BMW with a more spacious interior and practical features, making it suitable for everyday use.

The following is a list of the best-regarded BMW convertibles.

- BMW Z4: A sports roadster offering dynamic performance, a stylish design, and a premium interior.

- BMW 4 Series Convertible: Combines the luxury of the 4 Series with the pleasure of open-top driving.

- BMW 2 Series Convertible: A compact convertible known for its sporty handling, efficient performance, and sleek design.

- BMW 8 Series Convertible: A luxury grand tourer offering elegance, powerful engines, and advanced technology.

- BMW M4 Convertible: A high-performance version of the 4 Series Convertible, offering enhanced power and sporty dynamics.

Porsche convertibles

Porsche convertibles, particularly the 911 Cabriolet and the Boxster, are famous for their exceptional performance and precision engineering. The 911 Cabriolet is an iconic design widely recognized as a symbol of sports car heritage. The Boxster, known for its mid-engine layout, offers a more balanced driving experience. The Porsche convertible fleet combines speed, agility, and sophisticated engineering with the luxury of open-top driving.

The core Porsche convertibles are as follows.

- Porsche 911 Cabriolet: A legendary sports car known for its iconic design, exhilarating performance, and advanced technology.

- Porsche 718 Boxster: A mid-engine roadster offering excellent handling, a powerful engine, and a refined cabin.

- Porsche 718 Spyder: A high-performance version of the Boxster, known for its sporty dynamics and distinctive design.

- Porsche Taycan Turbo S Cross Turismo: An all-electric sports wagon combining performance, innovation, and practicality.

- Porsche Panamera Convertible: A luxury sports car offering spaciousness, sophisticated design, and high performance.

Audi convertibles

Audi convertibles, such as the Audi A3 Cabriolet and the Audi TT Roadster, are recognized for their luxury, advanced technology, and all-wheel drive capabilities. The A3 Cabriolet is focused on technological innovation and interior quality. The TT Roadster, however, is known for its sporty design and performance-centric mechanics. Audi’s signature Quattro all-wheel-drive system is available in many of their convertibles and enhances the cars’ safety, performance, and handling.

The most popular Audi convertibles are listed below.

- Audi A3 Cabriolet: A compact convertible known for its stylish design, efficient performance, and premium features.

- Audi A5 Cabriolet: A midsize convertible combining elegant design, comfort, and a refined driving experience.

- Audi TT Roadster: A sports convertible known for its iconic design, agile handling, and advanced tech.

- Audi R8 Spyder: A high-performance supercar offering exhilarating speed, striking design, and a luxurious interior.

- Audi S and RS Models: High-performance variants offering enhanced power, sportier design, and advanced driving dynamics.

Jaguar convertibles

Jaguar convertibles, especially the F-TYPE Convertible, have a distinctive design and powerful performance. The F-TYPE stands out from the pack thanks to its sleek, athletic bodywork and powerful drive capabilities that deliver a thrilling experience on every journey. Jaguar combines luxury with modern sports car dynamics to create convertibles that carry an aura of prestige.

The premier convertibles in the Jaguar fleet are as follows.

- Jaguar F-Type Convertible: A sports car offering a thrilling drive, luxurious interior, and distinctive Jaguar styling.

- Jaguar XK Convertible: A grand tourer known for its refined performance, elegant design, and comfortable cabin.

- Jaguar E-Type Convertible: An iconic classic sports car celebrated for its beautiful design and engaging performance.

- Jaguar XE SV Project 8: A high-performance sedan with limited production, offering extreme power and track-focused dynamics.

- Jaguar XF Convertible: A luxury sedan (though no convertible model as of my last update) known for its sleek design, spacious interior, and smooth performance.

8. Sports Car (Roadster)

Sports cars are high-performance vehicles designed with a focus on speed, handling, and aesthetic appeal. Sports cars typically feature a sleek, aerodynamic design and come equipped with powerful engines and a rear-wheel-drive layout, enhancing their performance capabilities. Sports cars usually have two seats, a low center of gravity, and a light total weight, which contributes to their heightened agility and speed.

Roadsters are a subset of sports cars that are characterized by their convertible tops, allowing for an open-top configuration. Roadsters embody the essence of sports cars but with an added emphasis on enjoying the drive in the open air. They are often even more focused on the driving experience, eschewing practicality for the thrill of the road.

What are the most notable sports car manufacturers?

Below are the top five Sports car manufacturers.

- Porsche: Renowned for the iconic 911, balancing performance and daily drivability.

- Ferrari: Offers high-performance sports cars with advanced technology and exceptional driving experiences.

- Lamborghini: Known for dramatic designs and powerful performance in their sports cars.

- McLaren: Sports cars from McLaren feature cutting-edge engineering and race-inspired technology.

- Aston Martin: Combines luxury with performance in sports cars like the Vantage.

Porsche sports cars

Porsche sports cars, particularly the iconic Porsche 911 and the Porsche 718 Boxster/Cayman are famous for their unique combination of performance, everyday usability, and engineering excellence. The 911, with its distinctive rear-engine layout, offers a unique driving experience that blends high performance with practicality. The 718 models are celebrated for their mid-engine balance and agility. Porsche delivers an exhilarating driving experience in sports cars featuring premium build quality and technological innovation.

The best Porsche sports cars are listed below.

- Porsche 718 Boxster: A mid-engine sports car known for its agile handling, sleek design, and open-top driving experience.

- Porsche 911 Carrera: An iconic sports car celebrated for its performance, handling, and timeless design.

- Porsche 718 Spyder: Offers a purist driving experience with a focus on agility, lightweight design, and sportiness.

- Porsche 550 Spyder: A classic and historic sports car known for its lightweight construction and racing heritage.

- Porsche 918 Spyder: A hybrid supercar combining cutting-edge technology, high performance, and eco-friendly efficiency.

Ferrari sports cars

Ferrari sports cars, such as the Ferrari 488 and F8 Tributo, stand out for their exceptional performance, cutting-edge technology, and iconic Italian design. Ferrari sports cars are famous for their powerful engines and superior handling; Ferraris offers a driving experience focused on raw power and agility. The Ferrari brand’s commitment to motorsport heritage is evident in the advanced aerodynamics and engineering that form the backbone of all of its sports cars. Ferrari’s exclusivity and prestige, combined with its track-inspired performance, sets its sports cars apart as symbols of luxury and high-performance automotive engineering.

Below is a list of the prime Ferrari sports car models.

- Ferrari 488 Spider: A high-performance sports car with a retractable hardtop, powerful turbocharged engine, and sleek design.

- Ferrari Portofino: A grand touring sports car known for its versatility, elegant design, and powerful V8 engine.

- Ferrari F8 Spider: Combines the performance of the F8 Tributo with a retractable hardtop for open-air driving.

- Ferrari 812 GTS: A front-engine V12 convertible offering exceptional performance, luxury, and a thrilling driving experience.

- Ferrari SF90 Spider: A plug-in hybrid supercar offering extreme performance, innovative technology, and a retractable hardtop.

Lamborghini sports cars

Lamborghini sports cars, including the Huracán and Aventador, are distinguished by their bold, aggressive styling and high-performance engines. Known for their distinctive and dramatic designs, Lamborghinis often feature scissor doors and striking aerodynamic shapes. Their sports cars’ performance is backed by powerful V10 or V12 engines that deliver exceptional speed and a thrilling driving experience. Lamborghini creates visually striking and performance-focused vehicles appeals to those looking to make a statement with their car choice.

The top sports cars offered by Lamborghini are listed below.

- Lamborghini Huracan Spyder: A luxury sports car offering a blend of performance, style, and the thrill of open-top driving.

- Lamborghini Aventador Roadster: Known for its dramatic design, V12 engine, and exhilarating performance in a convertible form.

- Lamborghini Gallardo Spyder: A predecessor in the Lamborghini lineup, offering high performance and striking design.

- Lamborghini Murcielago Roadster: A classic Lamborghini model known for its power, aggressive styling, and open-top experience.

- Lamborghini Sian Roadster: A limited-production hybrid supercar combining groundbreaking technology with extraordinary performance.

McLaren sports cars

McLaren sports cars, such as the McLaren 720S and McLaren GT, are renowned for their advanced engineering, lightweight construction, and race-derived technology. McLaren sports cars are renowned for their carbon fiber chassis, and each of their cars offers exceptional handling and performance. The focus on innovating aerodynamic design and powerful turbocharged engines are what give McLaren sports cars their impressive speed and agility. McLaren’s dedication to creating technologically advanced, performance-oriented vehicles set them apart in the realm of high-performance sports cars, but this comes at a premium price reserved for the highest-end segment of the market.

The leading sports cars from the McLaren brand are the following models.

- McLaren 720S Spider: A supercar offering a perfect balance of performance and comfort with a retractable hardtop.

- McLaren 600LT Spider: A track-focused sports car known for its lightweight design, powerful engine, and agility.

- McLaren 570S Spider: Combines the performance of the 570S Coupe with the exhilaration of open-top driving.

- McLaren Elva: An ultra-lightweight, open-cockpit road car offering a unique and immersive driving experience.

- McLaren GT Spider: A grand tourer combining long-distance comfort with the high performance of a sports car.

Aston Martin sports cars

Aston Martin sports cars, like the Vantage and DB11, are recognizable for their blend of elegant British design, luxurious craftsmanship, and performance. The Vantage is known for its engineering athleticism and distinctive style, while the DB11 combines grand touring comfort with powerful engine options. Aston Martin’s focus on creating vehicles that offer a refined and sophisticated driving experience while maintaining their timeless design sets their sports cars apart as a symbol of luxury, heritage, and automotive excellence.

The core sports cars manufactured by Aston Martin are listed below.

- Aston Martin Vantage Roadster: A luxury sports car known for its athletic performance, distinctive design, and open-top enjoyment.

- Aston Martin DB11 Volante: A grand touring convertible offering elegance, advanced technology, and a powerful engine.

- Aston Martin DBS Superleggera Volante: A high-performance convertible combining luxury, power, and sophisticated design.

- Aston Martin V12 Vantage Roadster: Known for its powerful V12 engine and exhilarating open-air driving experience.

- Aston Martin Valkyrie Spider: A hypercar offering extreme performance, advanced aerodynamics, and a revolutionary design.

9. Luxury

Luxury cars are the pinnacle of automotive excellence, combining advanced engineering, exceptional craftsmanship, and high-grade materials. Luxury cars offer unparalleled levels of comfort, including luxury interiors such as leather upholstery, high-quality audio systems, and advanced climate control. Many luxury cars often include customization options that cater to individual preferences and further justify the higher asking prices.

Luxury cars are distinguishable from standard vehicles thanks to their superior driving experience, powerful engines, and the frequent inclusion of cutting-edge technology. Luxury automobiles range in size from elegant sedans to spacious luxury SUVs, each designed to deliver a unique blend of style, prestige, and comfort perfectly suited to the needs and demands of their specific body type.

What are the most notable luxury car manufacturers?

The five core luxury car manufacturers are listed below.

- Mercedes-Benz: Mercedes’ luxury cars are known for their technologically advanced mechanics and stylish interiors, such as showcased in the E-Class Cabriolet.

- BMW: BMW offers sporty and dynamic luxury cars, exemplified by the Z4 Roadster.

- Audi: Audi luxury cars combine sleek design with advanced technology in models like the A5 Cabriolet.

- Lexus: Lexus’s luxury fleet includes luxurious convertibles with a focus on comfort and craftsmanship, such as the LC Convertible.

- Porsche: Porsche is renowned for their luxury cars like the 911 Cabriolet, combining speed with open-top driving pleasure.

Mercedes-Benz luxury cars

Mercedes-Benz luxury cars, such as the S-Class and E-Class, set themselves apart from the rest of the luxury car field with their blend of advanced technology, exceptional comfort, and meticulous attention to detail. The S-Class, which is widely considered Mercedes’ flagship sedan, offers innovative driver assistance systems and opulent interiors that exude luxury from front to back. The E-Class combines all of this with an underlying practicality that makes it a luxury car perfectly suited for daily use.

The five core luxury Mercedes-Benz cars are listed below.

- Mercedes-Benz S-Class: The flagship luxury sedan known for its exceptional comfort, advanced technology, and smooth performance.

- Mercedes-Benz E-Class: A midsize luxury sedan offering a perfect blend of refinement, technology, and comfort.

- Mercedes-Benz CLS-Class: A luxury sedan with a coupe-like design, known for its stylish aesthetics and powerful engines.

- Mercedes-Benz G-Class: A luxury off-road vehicle combining rugged capability with high-end interior luxury.

- Mercedes-Maybach S-Class: Represents the pinnacle of luxury with opulent features, unparalleled comfort, and superior craftsmanship.

BMW luxury cars

BMW’s commitment to delivering “The Ultimate Driving Machine” is clear to see in their range of luxury cars, which blend superior performance with high-end comfort and refinement. The 7 Series, BMW’s flagship model, offers a cutting-edge V8 turbocharged hybrid drivetrain and adaptive air suspension for improved handling and comfort. The 5 Series balances luxury with agility, providing a dynamic driving experience with a range of premium comfort features.

The top five BMW luxury cars are as follows.

- BMW 7 Series: BMW’s flagship luxury sedan, offering advanced technology, supreme comfort, and powerful performance.

- BMW 5 Series: A midsize luxury sedan known for its perfect balance of performance and comfort.

- BMW X7: A large luxury SUV offering spaciousness, refined comfort, and advanced technology features.

- BMW 6 Series Gran Turismo: Combines the luxury of a sedan with the versatility of a hatchback, offering a spacious and elegant interior.

- BMW 8 Series: A luxury grand tourer known for its sleek design, powerful engines, and premium comfort.

Audi luxury cars

Audi luxury cars, including models like the A8 and A6, are known for their sophisticated design, advanced technology, and the innovative Quattro all-wheel-drive system. The A8 is Audi’s flagship full-sized luxury sedan that boasts an eight-speed turbo-charged V6, adaptive cruise control, lane-centering, predictive adaptive suspension, and rear-wheel steering for the ultimate driving experience. The A6 is Audi’s mid-sized answer to the A8, with greater agility and a lower price.

The primary Audi luxury cars are listed below.

- Audi A8: Audi’s flagship luxury sedan, offering advanced technology, a luxurious interior, and a smooth ride.

- Audi A7: A luxury sportback known for its sleek design, refined performance, and high-tech interior.

- Audi A6: A midsize luxury sedan offering a blend of performance, technology, and sophisticated comfort.

- Audi Q8: A luxury SUV coupe offering advanced technology, dynamic performance, and a stylish design.

- Audi S and RS Models: High-performance versions of Audi’s luxury models, offering enhanced power, sportier styling, and advanced driving dynamics.

Lexus luxury cars

Lexus luxury cars, such as the LS and ES models, are keenly regarded for their focus on comfort, reliability, and refined craftsmanship. The Lexus LS is their flagship sedan and offers unparalleled luxury with a meticulously crafted interior and advanced safety features. The ES provides a more accessible entry into luxury with a lower price point yet still manages to maintain a high standard of comfort and build quality. Lexus offers reliability, exceptional build quality, and a smooth, quiet ride–appealing to those who prioritize comfort and dependability in their luxury vehicles.

The most popular luxury cars offered by Lexus are as follows.

- Lexus LS: The flagship luxury sedan from Lexus, known for its quiet cabin, advanced technology, and refined comfort.

- Lexus ES: A midsize luxury sedan offering a smooth ride, luxurious interior, and efficient performance.

- Lexus GS: A luxury sports sedan known for its balanced handling, powerful engine options, and comfortable interior.

- Lexus IS: A compact luxury sedan offering sporty handling, a sleek design, and advanced technology.

- Lexus LC: A luxury sports coupe and convertible known for its striking design, performance, and craftsmanship.

Porsche luxury cars

Porsche luxury cars, including the Panamera and 911, stand out for their exceptional performance and aesthetic appeal. The Panamera combines the practicality of a luxury sedan with the performance capabilities of a high-end sports car. The iconic 911 is synonymous with Porsche’s luxury heritage. Its distinctive design, powerful engine options, and unparalleled driving experience. Porsche places great emphasis on performance, alongside their high-quality craftsmanship to ensure their luxury cars remain the first choice for those seeking a high-end ride.

The premier luxury cars in the Porsche fleet are as follows.

- Porsche Panamera: A luxury sports sedan offering a blend of performance, luxury, and practicality.

- Porsche Taycan: An all-electric luxury sports sedan known for its exceptional performance and cutting-edge technology.

- Porsche 911: An iconic sports car offering a perfect balance of performance, luxury, and timeless design.

- Porsche Cayenne: A luxury SUV combining sports car performance with the versatility of an SUV.

- Porsche Macan: A compact luxury SUV offering sports car-like performance and a premium interior.

10. Electric

Electric cars are vehicles powered solely by electric motors. The advent of electric cars marks a significant evolution in automotive technology as a means to combat global emissions and reduce the economic reliance on the fossil fuel consumed by internal combustion engines.

They operate without the traditional internal combustion engine, instead relying on electric power stored in rechargeable batteries. The design of electric cars results in zero tailpipe emissions, which, in turn, contributes to long-term environmental sustainability. Electric vehicles (EVs) come in various sizes, from compact urban models to spacious SUVs, and offer solutions for the entire spectrum of driving needs and preferences.

Electric cars differ from conventional cars due to their quieter operation and instant torque delivery. Additionally, Electric cars feature regenerative braking, which recovers energy during braking, recycling it through to charge the battery.

What are the most notable electric vehicle manufacturers?

The top five electric car manufacturers are listed below.

- Tesla: Tesla is a pioneer in electric vehicles, offering cutting-edge technology and impressive range.

- Nissan: Nissan’s electric cars offer an affordable and reliable entry into the EV market with models such as the Leaf.

- BMW: BMW offers luxury electric vehicles like the i3 and i8, combining sustainability with premium features.

- Chevrolet: Chevrolet is a proud manufacturer of the Bolt EV, a practical and efficient electric car with a focus on affordability.

- Audi: Audi EVs all form part of the e-tron series, which blends Audi’s conventional luxury with electric vehicle technology.

Tesla electric cars

Tesla electric cars, including models like the Model S, Model 3, Model X, and Model Y, stand out for their long driving ranges, high-performance capabilities, and advanced autonomous driving features. The Tesla Model 3 offers an affordable entry into the world of electric vehicles and still delivers impressive performance. The Model X, with its unique falcon-wing doors, caters to the SUV market, and the Model Y provides a compact SUV experience, both delivering stellar efficiency thanks to Tesla’s signature technology. Tesla’s commitment to innovation, superior range, and comprehensive supercharging network positions them as leaders in the electric vehicle market.

The top five models of Tesla electric cars are listed below.

- BMW 2 Series Coupe: A compact coupe known for its sporty handling, stylish design, and engaging driving experience.

- BMW 3 Series Coupe: Offers a balance of performance and luxury in a compact coupe form, with sleek styling and a comfortable interior.

- BMW 4 Series Coupe: A luxury coupe combining elegant design, advanced technology, and dynamic driving performance.

- BMW 8 Series Coupe: A grand tourer offering a blend of luxury, performance, and cutting-edge technology in a sleek design.

- BMW M4: A high-performance version of the 4 Series, known for its powerful engine, sporty handling, and aggressive styling.

- BMW i8: A plug-in hybrid sports car offering futuristic design, eco-friendly performance, and innovative technology.

Nissan electric cars

Nissan electric cars, notably the Nissan Leaf, are recognized for their accessibility and practicality in the electric vehicle market. The Leaf stands out for its affordability, making electric vehicles accessible to a broader range of consumers. Nissan EVs provide a reliable and efficient driving experience and are suitable for daily commuting and urban driving. Nissan is focused on producing electric cars that balance cost, functionality, and reliability, an ethos that sets them apart from their competitors.

The core electric cars offered by Nissan are as follows.

- Mercedes-Benz C-Class Coupe: A compact luxury coupe offering a stylish design, sporty performance, and advanced features.

- Mercedes-Benz E-Class Coupe: A midsize luxury coupe known for its elegant design, comfortable ride, and high-quality interior.

- Mercedes-Benz S-Class Coupe: A large luxury coupe offering a blend of opulence, advanced technology, and powerful performance.

- Mercedes-Benz CLA Coupe: A compact four-door coupe known for its sleek styling, sporty dynamics, and modern technology.